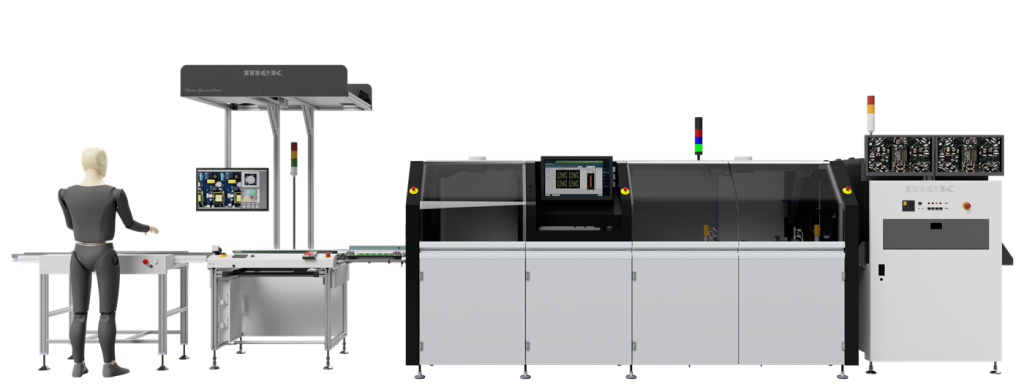

Mek VeriSpector AOI is a low cost AOI system for inspection of THT components before they enter the wave or selective soldering machine.

With extremely short inspection times of under 5 seconds the VeriSpector AOI system allows manufacturers to perform real time assembly and placement inspection, carry out repairs on the fly and prevent defects before they move into the next process. In manual assembly there is a much increased risk of faults. The instant feedback provided to operators by VeriSpector, helps eliminate the risk of failures and increase the quality and effectiveness of manual and semi-automatic manufacturing processes. Significant yield improvements are realized as a result.

Inline Operation

Typically, there are multiple manual assembly stations in factories that ideally require separate optical inspection at each station. To minimize AOI investment costs, an inline configuration is therefore preferable.

Developed in cooperation with Nutek, a brand well known in Board Handling & Traceability Equipment, the inline version of the successful VeriSpector THT AOI delivers maximum robustness and compatibility. A wide range of options are available to fully automate the inspection process.

Powerful, Tried & Tested Software

Mek VeriSpector is an optical inspection system which uses the renowned Marantz 22X Software. It is easy to program while maintaining the power and speed of the inspection algorithms used for many years within the PCB (Printed Circuit Board) assembly industry.

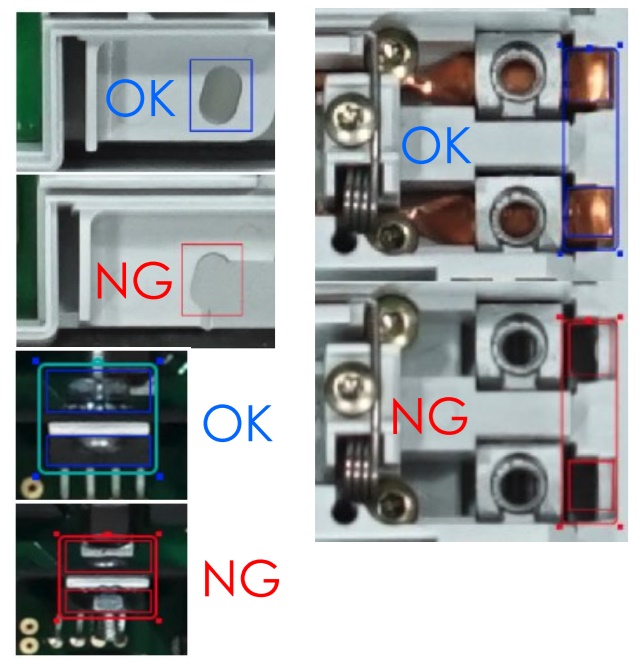

Flexible Inspection Possibilities

The VeriSpector AOI is designed for a wide verity of inspection needs including:

- Presence/absence

- Orientation

- Shape

- Offset

- Polarity

- Text verification

- Fiducial reading

- Colour check

- 1D and 2D barcode reading

- Assembly materials fittings

- Damaged objects

- And many more.

The maximum size of PCB or object to be inspected is 750mm x 500mm (29.5″x19.7″) whilst the minimum is 460x300mm (18×12”″) when using the maximum zoom setting on the zoom lens

A 24MP camera for crisp, clear resolution comes as standard, with a high definition lens to capture fine details. Options are available to upgrade to 42Mp or 60Mp cameras depending on the application requirements. The resolution can be increased if a PCB size less than the maximum of 750×500 is required. Detected defects can be displayed via red circles on a PCB Map or by NG images.

A 24MP camera for crisp, clear resolution comes as standard, with a high definition lens to capture fine details. Options are available to upgrade to 42Mp or 60Mp cameras depending on the application requirements. The resolution can be increased if a PCB size less than the maximum of 750×500 is required. Detected defects can be displayed via red circles on a PCB Map or by NG images.

The overhead orthogonal camera and LED lighting system are optimised for colour and glare, allowing operators to continue performing assembly tasks under normal lighting conditions.

Downloads

Downloads

Videos

Videos

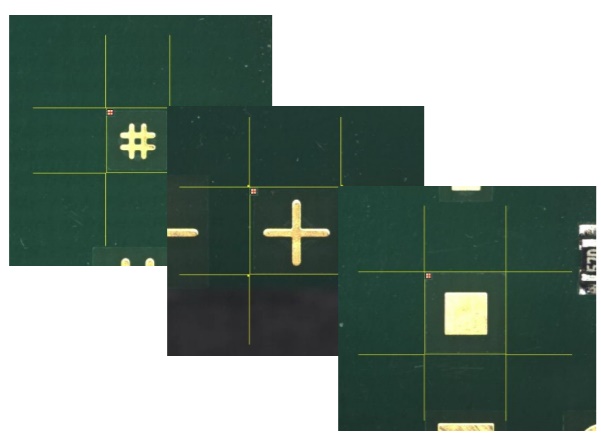

Fiducial Recognition

Amongst the many capabilities of the VeriSpector assembly station AOI is Fiducial Recognition.

The recognition of fiducials is an important feature, ensuring high repeatability of inspection programs. The VeriSpector uses the fiducial recognition algorithm provided by the Marantz 22x Software. VeriSpector can recognize a wide variety of fiducials, and when there is no fiducial available, it can use a photo as fiducial reference.

Connectivity and Traceability

VeriSpector is powered by Mek 22X AOI Software on Apple Mac ™ and is fully compatibility with Mek’s 22X AOI products such as SpectorBOX including Library, Fiducialling, Search, Text, Polarity, Bar Coding etc. BarCode reading is carried out by the 22X BarCode decoding engine. Base formats including Datamatrix, QRcode, Code 128 and Code 39 are supported and the system can handle multiple barcodes per fixture or panel. For total flexibility, an external BarCode reader can also be used.

As an option VeriSpector can also feature Mek Catch Software for MES gateways, repair & SPC on Windows 10 ™, integrating the storage of inspection data, including images.

Easy Integration

The VeriSpector Assembly Station AOI comes complete as an easy to assemble package to install the optical head with frame on the assembly station of the users’ choice. This frame holds all the system components; camera, lighting system, Apple Mac & monitor.

The VeriSpector is available in three different models, so you can choose the perfect camera for your inspection requirements.

Mek VeriSpector Models

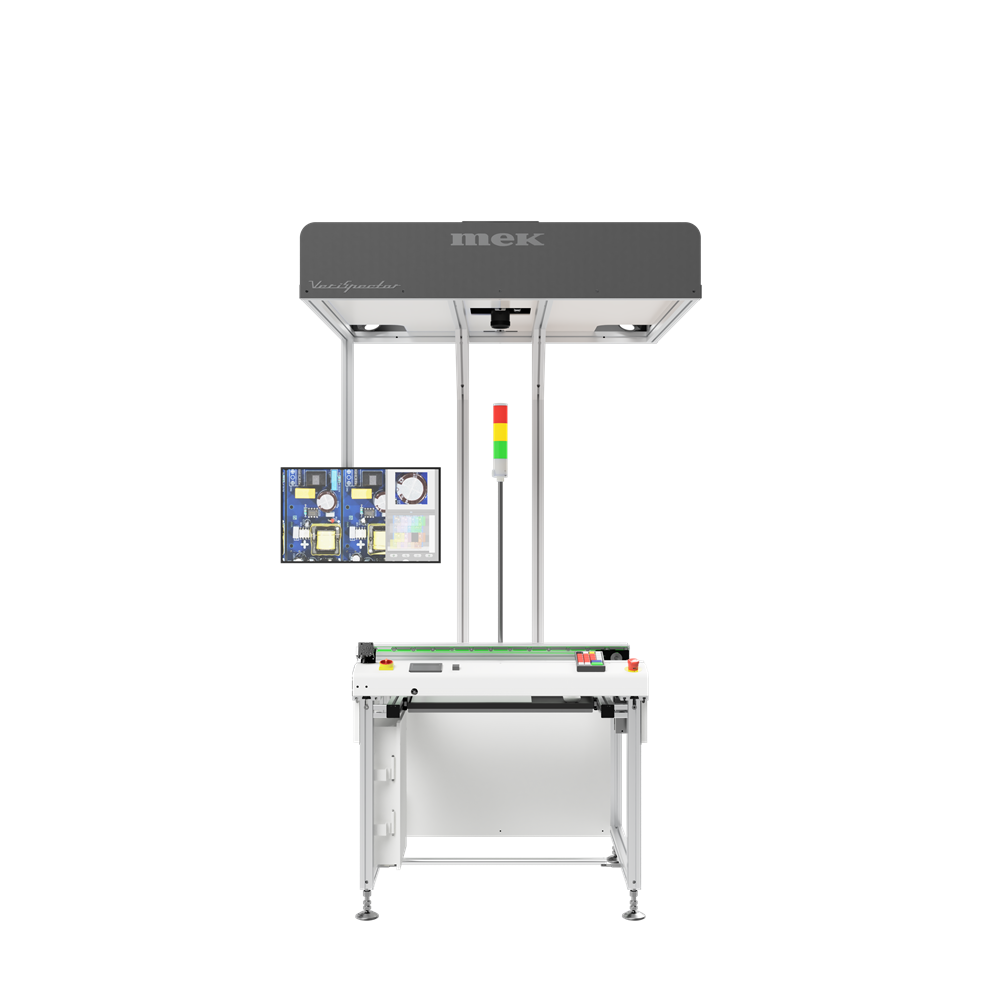

VeriSpector Inline AOI

Inline THT AOI With Standard Conveyer

- 1000mm Conveyor

- Keyboard/Mouse tray

- Sensor Stopper and slow down zone

- Touch Screen

- SMEMA Compatible

- Upstream Stopper

- 500 x 750mm Max PCB Size

- For PCB’s assemblies up to 6kg

VeriSpector Large Inline AOI

Inline THT AOI With 3-Stage Rework Conveyer

- 3-stage 1700mm Conveyor with Reject area

- Arm rest

- Space for mounting component trays

- Keyboard/Mouse tray

- Sensor Stopper and slow down zone

- Touch Screen

- SMEMA Compatible

- Upstream Stopper

- 500 x 750mm Max PCB Size

- For PCB’s assemblies up to 6kg

VeriSpector Manual THT AOI

Manual Assembly Station AOI